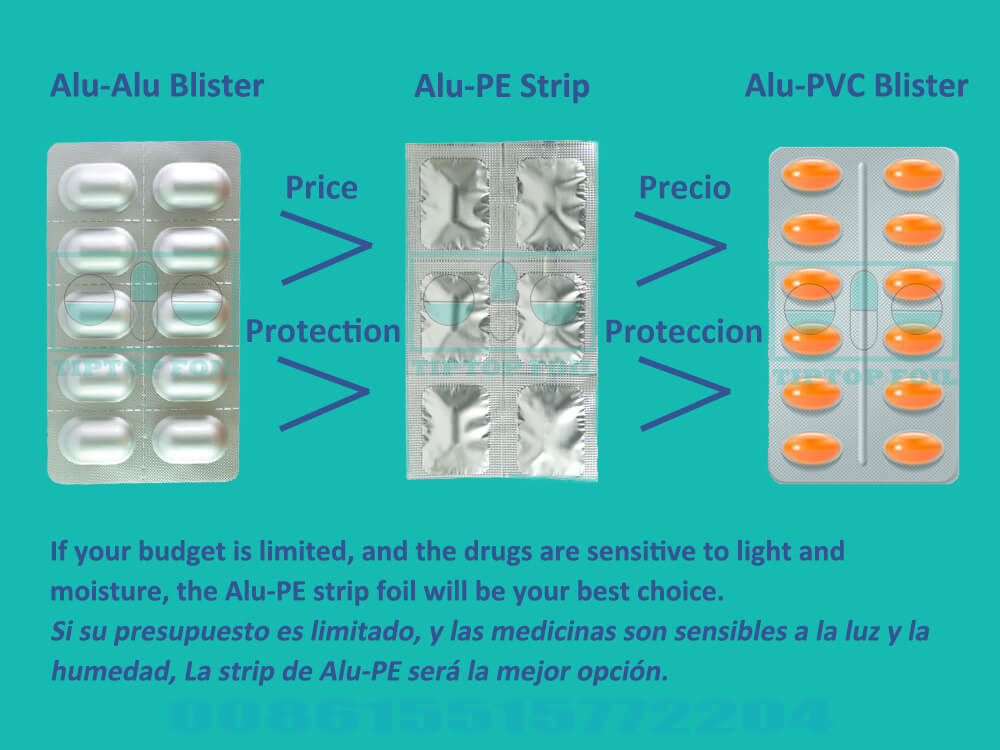

Strip Package VS Blister Package

Blister package and strip package are two popular forms of the primary packages for pharmaceuticals, nutraceuticals, medicals, like tablets, capsules, pills, etc.

farmaceutico-blister-empaque

Blister package is a form of unit-dose packaging, in which a semi-rigid blister/ cavity previously formedfilled with products and lidded with a heat-sealable backing material. Here, blister/ cavity/pocket is formed either a thermoforming or cold forming process.

Strip packaging is an alternative form of unit dose packaging, in which a pharmaceutical product is enclosed between two webs of heat-sealable flexible film through either a heated reciprocating platen or a heated crimp roller.

Strip Package VS Blister Package – Tiptop Joe

They both are unit-dose package, used for tablets, capsules, pills, other small size doses, etc., easy to handle and carry.

But there are also some differences between them.

| No. | Item | Blister Package | Strip Package |

| 1 | Material cost | Alu-PVC blister is low, Alu-Alu blister is high | Strip is rated between the two types of blister pack |

| 2 | Barrier protection | Alu-PVC blister is lower, Alu-Alu blister is the highest and with light resistant | Strip is high, also with light resistant |

| 3 | Mechanical protection | Better, cavities are semi-rigid | Lower, pockets are soft |

| 4 | Appearance | Better with different shapes of blisters | Lower |

| 5 | How-to-use | Peeling or pushing | Tearing |

| 6 | Child resistance | Lower | Higher |

| 7 | Application | More, especially the plastic blister is being used for food, hardware, toys, etc. | Less, mainly for pharmaceuticals & medicals. |

| 8 | Pocket area for drugs | Smaller (Alu-PVC blister is smaller than Alu-Alu blister) | Bigger than both two types of blister |

| 9 | Packagingspeed | higher | lower |

| 10 | Difficulties during packaging | It may occur the cracking caused by un-matched molds during cold forming | Pockets are too tight, thus, wrinkling of the seal area or perforation of the pocket periphery may occur. |