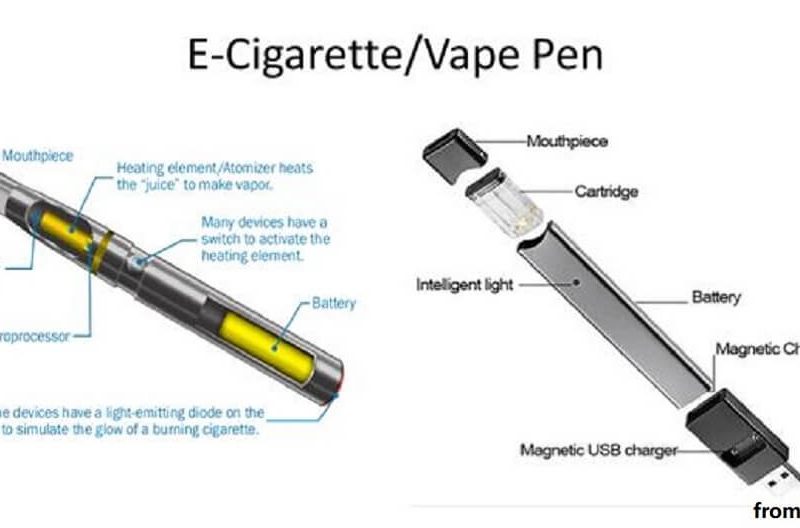

Traditionally the PVC rigid film is being used as blister package for the cartridge of E-cigarette. It is transparent, formable, cost-effective, but with bad moisture-proof, which can lead to the dead of electronic parts of vape.

E-cigarette Vape Components

The package requirements in the electronic cigarette industry:

- High moisture-proof: to avoid the electronic parts damped.

- Good oxygen-proof: to avoid the electronic parts oxygenized.

- High transparency: perfect visible to customers.

- Easy formable: available for package of cartridge in different sizes on the same packaging machine.

Types of high barrier film

PVC/PVDC for Vape Blister Package

Normally the rigid plastic film is included PVC, PVC/ PVDC, other laminated film. Because of PVC’s lower barrier against the moisture, so PVC/ PVDC and PCTFE/ PVC(Aclar) are developed for improving.

1. PVC

Rigid PVC film is the most cost-effective formable film, but with lower moisture-proof, which can lead to the dead of electronic parts of vape.

2. PVC/PVDC

PVDC is with higher moisture-proof property, so being used widely as the high barrier film. It is mostly coated on the PVC film, such as 60 & 90gram per square meters.

To pack the cartridge, the common specification is PVC 350mic + 60gsm or 90gsm.

Higher coating quantity, better barrier properties.

3. PCTFE/PVC

PCTFE/PVC(Aclar) laminate is with better vapor barrier than PVC/PVDC film. But with patent protection, the PCTFE is quite expensive.

Comparison entre them

| Material | Cost | Formable | Moisture-proof | Oxygen-proof | Sealable | Visible |

| PVC | Low | Good | Low | Middle | Good | Good |

| PVC/PVDC | Higher | Good | Higher | Higher | Good | Good |

| PCTFE/PVC | Highest | Good | Highest | Higher | Good | Good |

In one word, the PVC/PVDC film is the best choice to pack cartridge of E-cigarette.