PVDC is polyvinylidene chloride, known for its excellent gas barrier properties against water, oxygen and many gases (aromas). It also has better corrosion resistance than PVC due to its higher chlorine content and is sometimes copolymerized with PVC to improve its performance.

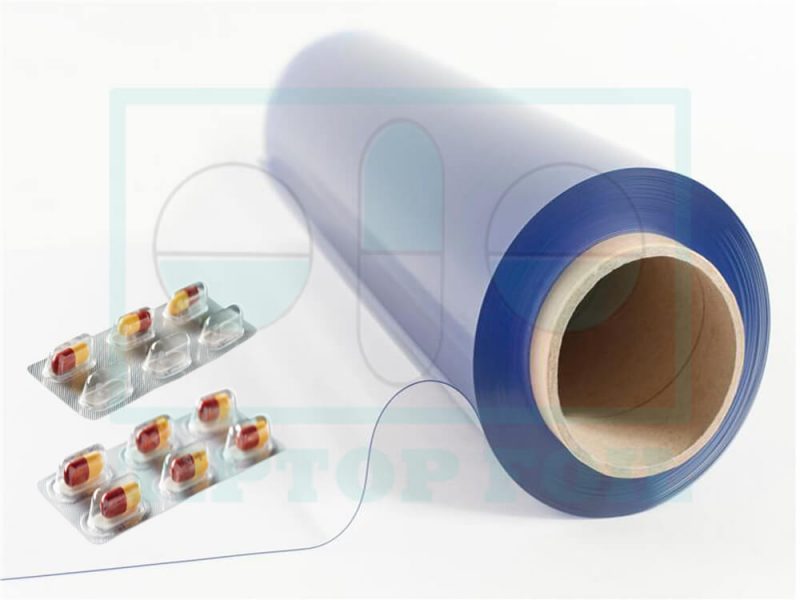

Blister Film Rigid PVC/PVDC

PVDC is applied as an aqueous coating over the PVC rigid film; its weight is expressed in grams per square meter (gsm or g/m2). 40gsm/ 60gsm/ 90gsm/ 120gsm are common. Its performances are in proportion to the weight of PVDC coating.

Compared with PVC rigid film, PVC/PVDC duplex film has much better barrier properties, special against the moisture, a ideal packaging film for humid-sensitive medicines. meanwhile it can be used on the same blister packaging machine for PVC film, no new nachines needed, which save your investment.

Normally the PVC/PVDC is transparent (crystal). It allows patients to have a look at the capsule or tablet directly, which is much easier to identify medicines on a given day.

Tiptop’s PVC/PVDC film is manufactured by the proven technology, the qualified materials, the state-of-the-art machines and skilled workers to meet the high quality requirements of the pharmaceutical & food Industry, and it is registered and active in China FDA now.

Based on more costs during production, the PVDC rigid price will be a little higher. For exact one, please inquiry me now.

Here are Tiptop’s regular structures of rigid PVC/PVDC film in Tiptop:

| Product code | Structure | Thickness | Weight | Max. width |

| TTF-PVDC-1 | PVC 250mic/ PVDC 40gsm | 275±20mic | 385±30gsm | 800mm |

| TTF-PVDC-2 | PVC 250mic/ PVDC 60gsm | 285±20mic | 405±30gsm | 800mm |

| TTF-PVDC-3 | PVC 250mic/ PVDC 90gsm | 305±20mic | 435±30gsm | 800mm |

Please kindly be noted: other structure is also available, like PVC 200mic/ PVDC 60gsm, etc.

Colored PVC/PVDC Film

Duplex PVC/PVDC also can be colored with pigment, such as red, amber, white, green, etc. to resist the visible light, which is one good choice for light-sensitive products. meanwhile the film with UV filters is availiable in Tiptop, better carrier for medicines consumed in the areas of rich sun shines.

Tiptop is able to do the colored PVC/PVDC blister film as your request. In this case, it is best that you could offer us the original colored sample to prepare our sample for you to test and confirm the quality before the bulk production. Otherwise we could directly offer our colored sample; you check its color and do machine trial, then feedback to Tiptop.

Our pharmaceutical PVC rigid film is being produced of pharmaceutical grade resins, in clean room meeting all GMP requirements. The whole production progress is traceable: each batch of goods is with records of raw materials, production & QA/QC, test & release, delivery, etc, which will be kept for at least 3 years.

Please kindly be noted: it will take 10-15days to prepare the sample.

An additional layer of PE is introduced between PVC and PVdC to improve the barrier properties like OTR & WVTR. This film is termed as Triplex due to the 3-layered structure. This layer of additional coating is to increase the shelf life of the product.

Triplex films can give a high gloss or metallic finish to the product.

Normally PE layer is 30micron thick, with two options: easy to peel-off or not.

PVC layer and PVDC coating options are same with duplex film, so the triplex film also suits all types thermo forming machines.

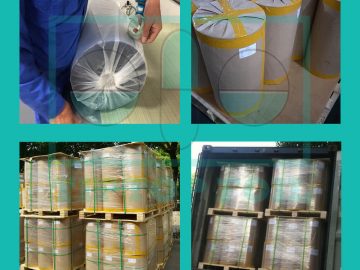

Carton Pack

1.1 each roll is sealed in PE bag, loaded into carton. Cartons stack into shipment container directly.

Aproxi 18-21tons for one 20ft FCL load, which depends on roll widths & weight.

1.2 each roll is sealed in PE bag, loaded into carton. Cartons stack on plywood pallet, with four edge protectors and plastic film wrapping.

Aproxi 18-20tons for one 20ft FCL load, which depends on roll widths & weight.

pharma-rigid-pvc-jumbo-roll-pack

roll is wrapped by PE film and Kraft, with two edge protectors, then stack on plywood pallet by eye-to-sky, and covered by plastic film.

Aproxi 16-20tons for one 20ft FCL load, it depends on the width & weight of each roll.

They both are strong enough and an effective shield against the dusts or damages during shipment to your company,