PVC/PE Duplex Laminate is a superior barrier, flexible packaging material designed to address the unique challenges of liquid and suppository medications.

The duplex structure integrates the rigidity and chemical resistance of PVC with the flexibility and moisture resistance of PE, creating a synergistic solution that safeguards product integrity from production to end-user application.

Compatible with automated vertical-forming-filling-sealing(VFFS) systems, it streamlines packaging processes while minimizing contamination risks.

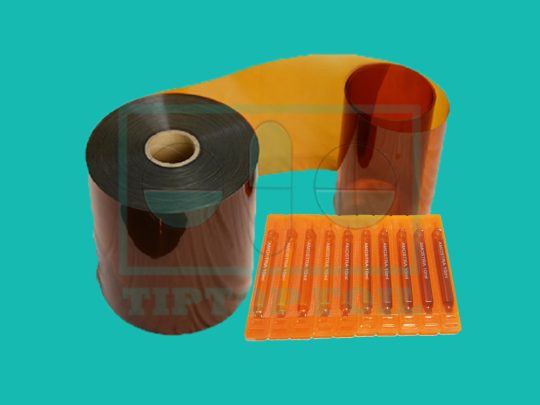

Compared with the glass ampaule, the PVC/PE ampolla is not fragile and portable, high tensile, good sealing, friendly in the progress of storage and transportation. And another key factor is cost effictive, with only half cost of the glass alternative.

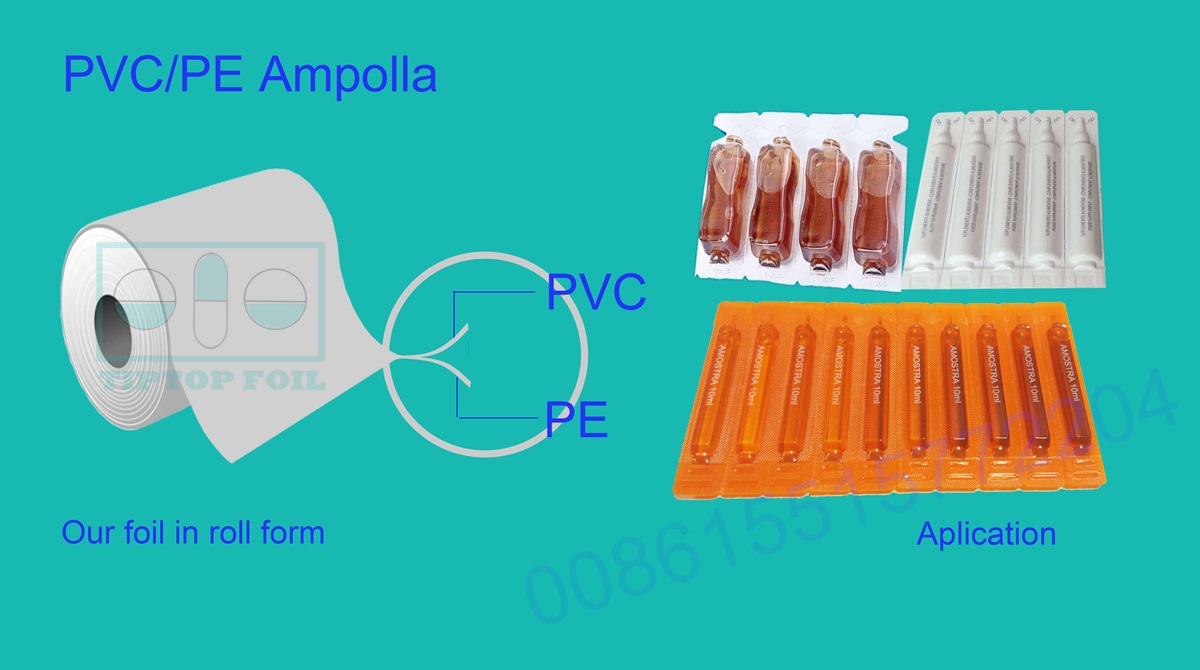

The PVC/PE features a unique dual-layer structure:

Outer PVC Layer: Provides rigidity, puncture resistance, and excellent clarity for product visibility.

Inner PE Layer: Ensures chemical inertness, acts as a protective barrier between the medication and PVC; also be the self-sealing material by heating.

This hybrid design leverages PVC’s mechanical strength while mitigating potential interactions between sensitive drug formulations and packaging materials.

Exceptional Barrier Protection

Liquid Medications: The film’s robust barrier properties prevent leakage, evaporation, and oxygen ingress, critical for preserving the stability of syrups, suspensions, and injectables.

Suppositories: Its airtight seal protects sensitive formulations from humidity and microbial contamination, ensuring consistent dosage and shelf life.

Material Compatibility & Safety

Formulated with pharmaceutical-grade resins free of plasticizers and harmful additives, the film complies with FDA, EU, and other global regulatory standards.

Non-reactive with active pharmaceutical ingredients (APIs), excipients, or oils commonly used in suppositories.

Durability & Adaptability

Resistant to tearing, punctures, and temperature fluctuations (-20°C to 40°C), making it suitable for cold-chain logistics and diverse storage conditions.

Compatible with gamma irradiation, ethylene oxide (EtO), and autoclave sterilization methods.

User-Centric Design

Easy-to-tear perforations and clear printing surfaces enable tamper-evident features, dosage instructions, and branding opportunities.

Available in customizable thicknesses (e.g., 80–200 microns) and sizes to fit single-dose sachets, blister packs, or strip packaging.

Sustainability Considerations

While prioritizing functionality, we offer PE-rich variants with reduced PVC content to align with eco-friendly initiatives, without compromising performance.

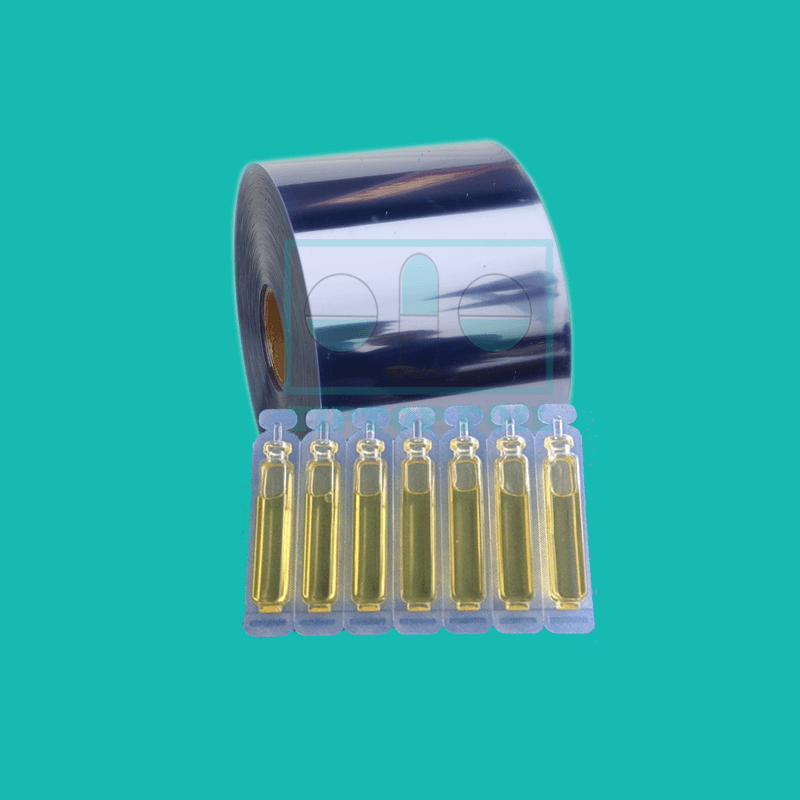

pvc-pe-duplex-ampolla-tiptop

Our PVC/PE duplex laminate is being produced of pharmaceutical grade resins, in clean room meeting all GMP requirements. The whole production progress is traceable: each batch of goods is with records of raw materials, production & QA/QC, test & release, delivery, etc, which will be kept for at least 3 years.

Here are our regular structures of PVC/PE duplex laminate in Tiptop:

|

Product code |

Structure | Thickness | Weight | Max. width |

|

TTP-PPE-1 |

PVC 200mic/ PE 30mic | 230±20mic | 300±25gsm | 800mm |

| TTP-PPE-2 | PVC 250mic/ PE 50mic | 300±25mic | 380±30gsm |

800mm |

| TTP-PPE-3 | PVC 300mic/ PE 50mic | 350±30mic | 450±40gsm |

800mm |

Liquid Pharmaceuticals: Oral solutions, eye/ear drops, topical lotions, and injectables.

Suppositories: Rectal, vaginal, and urethral formulations with lipid or polymer bases.

Diagnostic Kits: Sterile packaging for medical devices or reagents.

Contact us today to request samples, technical specifications, or collaborate on custom packaging designs tailored to your needs.

in Tiptop, there is two types of packing:

For slitted rolls:

each roll is sealed in PE bag, loaded into carton. Cartons stack on plywood pallet, with four edge protectors and plastic film wrapping.

Approx 16-18tons for one 20ft FCL load, which depends on roll widths & weight.

Carton Pack

For jumbo rolls:

roll is wrapped by PE film, then suspended in plywood case with silica gels.

Approx 18-20tons for one 20ft FCL container, which depends on roll widths & weight.

plywood case for jumbo roll foil

They both are strong enough and an effective shield against the dusts or damages during shipment to your company,