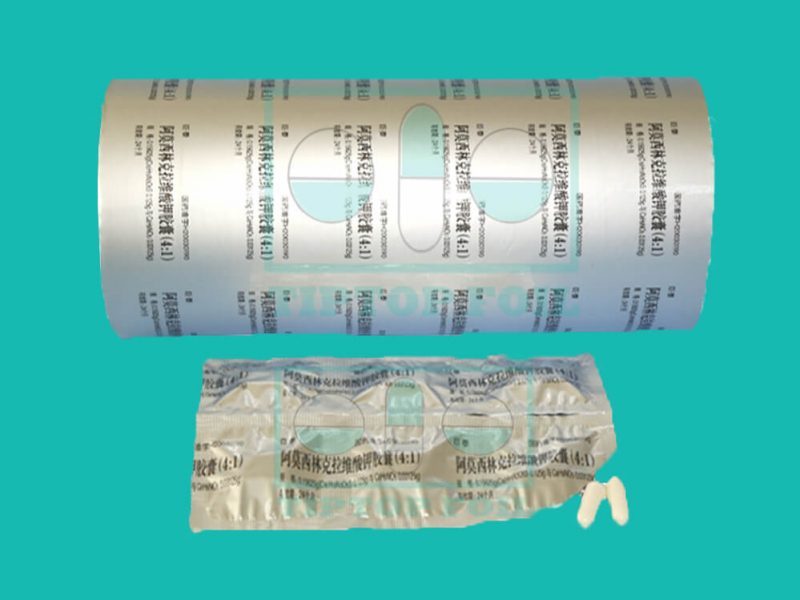

Medical Strip Laminate is another packaging solution for tablet, capsule, pill, etc., it is also made of two parts: the same type of converted foils (Alu/PE) by heat sealing, so the strip pack is not transparent, excellent protection against UV rays.

Medical Strip Laminates

Since the product is individually sealed into each pocket and released by easy-tear edges, it is easy to carry and friendly to customer to consume as the using indication printed on the lidding foils.

The PE side contact with drugs directly, and is sealed with each other by heating, no heat sealing lacquer needed, which is safer for drugs.

The Alu/LDPE laminate is with two-layer structure: aluminum foil and PE film, soft temple aluminum is varnished with primer for printing on one side, and laminated with LDPE film on another side.

Similar with Alu-Alu blister foil, it is also totally against the visiable light and UV rays, and nearly 100% resistant to moisture, oxygen, so it is another perfect primary packaging barrier for high sensitive pharmaceuticals.

On the other hand, its unit price is lower than Alu-Alu blister foils.

Tiptop’s Alu/PE strip film is manufactured by the proven technology, the qualified materials, the state-of-the-art machines and skilled workers to meet the high quality requirements of the pharmaceutical & food Industry, and it is registered and active in China FDA now.

Here are Tiptop’s regular structures of medical strip laminate:

| Product code | Structure | Thickness | Weight | Max. width |

| TTP-SPF-1 | Primer 1gsm/ Alu 30mic/ PE 38mic | 75±6mic | 125±10gsm | 800mm |

| TTP-SPF-2 | Primer 1gsm/ Alu 40mic/ PE 38mic | 86±7mic | 146±10gsm | 800mm |

| TTP-SPF-3 | Primer 1gsm/ Alu 40mic/ PE 50mic | 97±8mic | 160±12gsm | 800mm |

Please kindly be noted:

The printed Alu/PE strip foil is available in Tiptop, normally in one or two colors.

The printed Alu/PE strip foil is available in Tiptop, normally in one or two colors.

In this case, the printing artwork is necessary to make the printing cylinder firstly; if no printing design, the original sample or clear images are very helpful, we will work on the draft for you to confirm before sample and bulk production.

Our medical strip laminate is being produced of pharmaceutical grade resins, in clean room meeting all GMP requirements. The whole production progress is traceable: each batch of goods is with records of raw materials, production & QA/QC, test & release, delivery, etc, which will be kept for at least 3 years.

The cylinder will be available for the following orders with same printing. But if printing artwork is different, like a letter, a number, layout, etc, new cylinder will be needed.

Tiptop’s partner of print cylinder is professional and good at making the exact and durable one for bulk order in the future.

Please kindly be noted: it will take 7-15days to prepare the sample.

Based on more costs during production, the price of printed strip laminate will be a little higher. For exact one, please inquiry me now.

in Tiptop, there is two types of packing for medical strip laminate:

Carton Pack

1.1 each roll is sealed in PE bag, loaded into carton. Cartons stack into shipment container directly.

Aproxi 16-18tons for one 20ft FCL load, which depends on roll widths & weight.

1.2 each roll is sealed in PE bag, loaded into carton. Cartons stack on plywood pallet, with four edge protectors and plastic film wrapping.

Aproxi 16-17tons for one 20ft FCL load, which depends on roll widths & weight.

plywood case for jumbo roll foil

roll is wrapped by PE film, then suspended in plywood case with silica gels.

Approx 18-20tons for one 20ft FCL container, which depends on roll widths & weight.

They both are strong enough and an effective shield against the dusts or damages during shipment to your company,