What PVC PVDC cost consists of?

PVC PVDC cost consists of resins’ and additives’ price. Resins for PVC/PVDC or PVC/PE/PVDC, PVDC emulsion is another key material, key part of cost.

Annual Trend of PVC PVDC cost

The production progress of rigid PVC is

Weighing resins & additives → Mixing them → Melting them → Rolling → Rewinding → Slitting → Packaging.

The production progress of PVC PVDC is

Rigid PVC making → Coating PVDC → Rolling → Rewinding → Curing → Slitting → Packaging.

In China market, there are two sources of resins: coal & petroleum. Coal is richer than petroleum in China, so many codes of resins are made from coal, SG-5 is one major code of resins for rigid PVC & PVDC as pharmaceutical blister packages.

Meanwhile, SG-5 cost is lower than the resin made from petroleum.

Rigid PVC is made of SG-5 resins with little quantities of additives, which means that the SG-5 pricing largely affect the cost of final products.

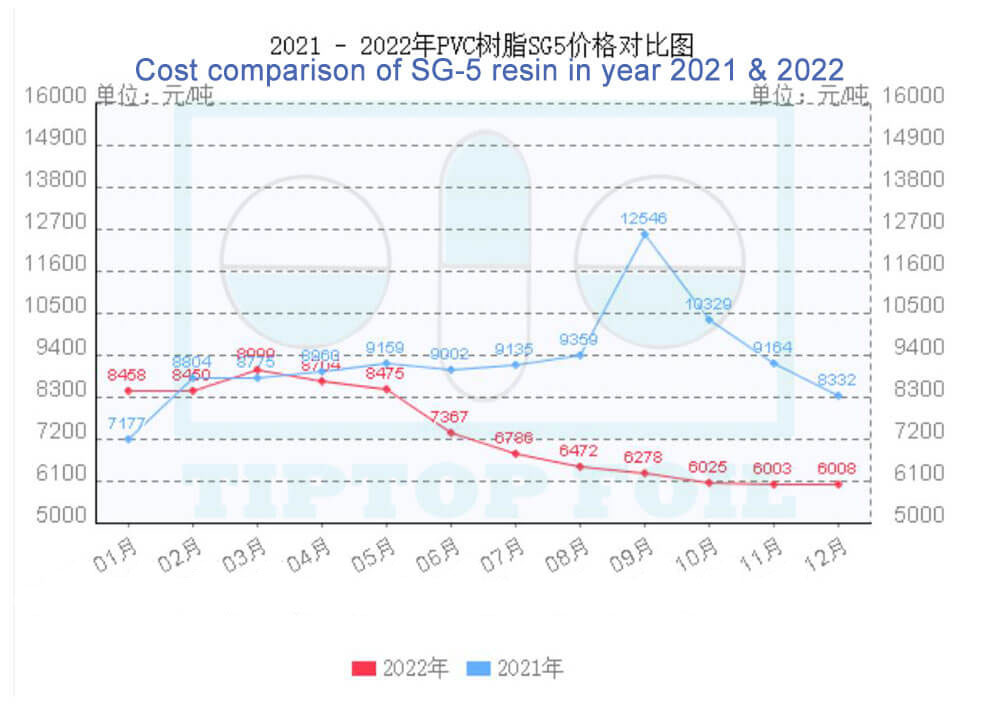

In September & October of year 2021, in order to get higher price, the coal mines reduced its output, beside winter (November – February) is the peak season of coal consumption in Northern of China, so the market worried about the supply of resins, and there was a lot of hot money involved, so SG-5 price raised heavily, after the interference of government, you can see that the price slid rapidly.

In the whole year 2022, the SG-5 cost was with the down trend in general, because March – May is traditional busy season of production in China.

In year 2023, my opinion is that the SG-5 resin pricing will be waved at low level, so it would be good chance to import rigid PVC & PVC/PVDC from China. Another good news is that China government canceled almost limited actions against COVID-19 in December, 2022, the production and transport of ingots & foils are coming to be normal now.

Generally welcome to your inquiry to info@tiptopfoil.com, the latest & best price will be replied to you soon.